Cigar light is an essential part of the cigar smoking culture. They come in many different shapes and sizes and there is a wide range of prices you will find when looking for one.

It’s not something you use once and throw it away. You can and should refill it.

If you’ve bought your cigar lighter at your local cigar shop, they might refill for you, but let me teach you how to fish so you can do it on your own.

It’s simple to refuel your refillable butane lighter. Refill cans are widely accessible, from your local tobacco shop to Amazon.

If you’ve just purchased a cigar lighter online, you may have noticed that all lighters are shipped empty for safety and security reasons.

Or perhaps your lighter has run out and you need to know how to replenish it.

Here’s what you need to do first…

How to refill your butane cigar lighter step by step

Step 1: Purchase high-quality butane.

This is one of the most crucial tip for keeping your quality lighter in good operating order for a long period. Cheap butane does not burn as cleanly, and the impurity of the gas can cause blockage or failure of the burner valve. The number of times butane has been refined determines its quality; the higher the number, the better the quality.

Which brand of butane fuel should you use for refill your cigar lighter?

Premium butane brands that we recommend (Colibri, Vector, Lotus, Prometheus, or any triple refined butane) come in 10-13 oz. cans with a metal fill tip nozzle. Non-premium butane (Clipper, Ronson, Sun) and brands with plastic fill tip nozzles are not recommended due to unpredictable ignition and performance.

Here’s my top 3 recommendations:

- PREMIUM BUTANE GAS: Colibri butane is the cleanest available at 99.9994% purity. Produced to the exacting standards required by high-performance jet-flame lighters, resulting in fuel so pure it does not require repeated filter-ing, like other brands.

- BURNS SMOOTHLY: This high-quality butane burns hot, clean, and consistent every time. The Colibri butane gas cartridge creates a fine pure flame ideal for high-end.

- ODOR & FLAVORLESS: Its purity level means it will not affect the flavor of your or tobacco, so you can enjoy a measurably better experience.

- Receiving 3 Cans of 90ml (3.04 oz) Lotus Butane

- Near Zero Impurities

- Made In England

- The finest Butane Fuel

- No Shipping Outside US Land

- Refill with Vector Quintuplus Butane

Step 2: Empty the lighter.

Because lighters are frequently warmer than our refill canisters, there is a large pressure mismatch. The pressure within that lighter is substantially higher than the pressure in your 68F/30psi butane refill.

Whether you had your cigar lighter in your car or it’s summer. The butane in your lighter is unlikely to meet the temperature and pressure of the new butane canister. While it may be preferable to chill your lighter for 10-15 minutes before pulling out the butane can. Most likely, you discovered your lighter was empty because you needed to smoke right now.

Before each refill, the tried and true recommendation has always been to purge your lighter by depressing the refill valve and emptying the trapped air. Also, do not immediately refill your lighter after using it. Allow enough time for the lighter to cool down.

If you follow the easy methods outlined here, your lighter will last for many years.

- Insert a small tool, such as a screwdriver, into the refill nozzle. You can use a pen.

- Press down to let any trapped air out of the lighter.

- Repeat for a few seconds or until no air escapes from the lighter.

- Reduce the flame’s height.

Step 3: Lower your flame height

If you’re out of fuel, you might have increased the flame height so you can attempt to get every last fuel you can get. But once you refill it, that flame height is going to burn your beard or eyebrows, or worse, your face.

Some variants include an adjustable wheel that eliminates the need for a screwdriver. Some lighters include a key for turning the adjustment screw.

I’m using a lighter that I can turn left to turned down the flame height. So I can’t show you how to use the following method but if you can’t simply adjust it with the wheel, read the following:

You’ll see a (+) and a (-) at the bottom of your lighter. You need to lower the flame height by twisting CLOCKWISE towards the (-) with a little screwdriver, a coin or even your thumb, if you have nails. The flame height adjuster on the bottom of the lighter should be adjusted to minimum. If it’s not moving in that direction, it’s likely that it’s already on the lowest setting

Step 4: Position of the lighter and the can

Shake the can of butane refill.

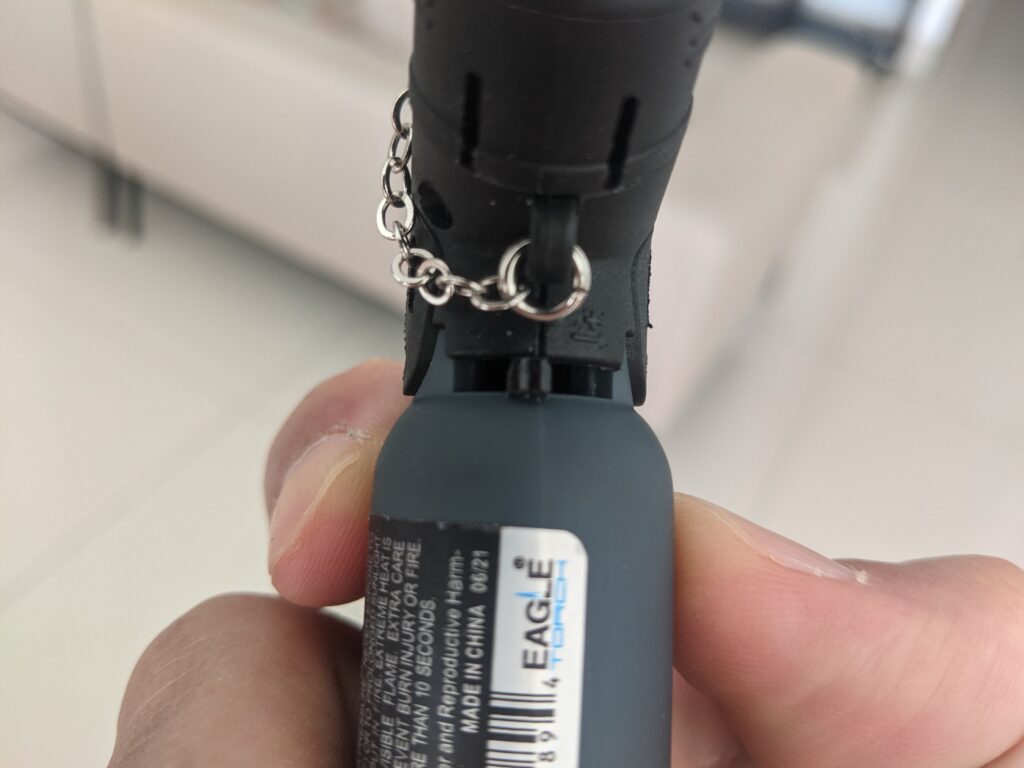

Both the lighter and the can should be facing down, and place the can nozzle into the lighter. This helps avoiding air entering the fuel tank when you go to fill it up.

Press the tip of the refill can firmly against the inlet valve for 4-5 seconds. Repeat 2-3 times more.

Insert the can’s nozzle into the lighter’s refill valve (again, with the lighter upside-down). Hold the can down for 5-10 seconds.

This step may need to be repeated 3-4 times before the lighter is entirely filled.

Keep in mind that when pressing the refill can onto the lighter, you should press firmly but not too forcefully. Typically, you want to hear a little hissing coming from the can. The hissing will stop once the lighter is full. Pushing too hard may result in no butane entering the lighter.

Step 4: Wait a bit

Because butane is extremely cold, you will notice your lighter becoming cold when new butane enters the tank. Allow 3-4 minutes for the gas and lighter components to come up to room temperature.

Allow your lighter to sit until the fuel returns to room temperature. Then, spin the screw in small increments towards the plus symbol (+) to open the flame adjustment valve and light your lighter.

jay

Self proclaimed cigar expert. I've been smoking since 2010. I've practically lived at a cigar lounge from 10am to 10pm and trying every new cigar that came out for years.